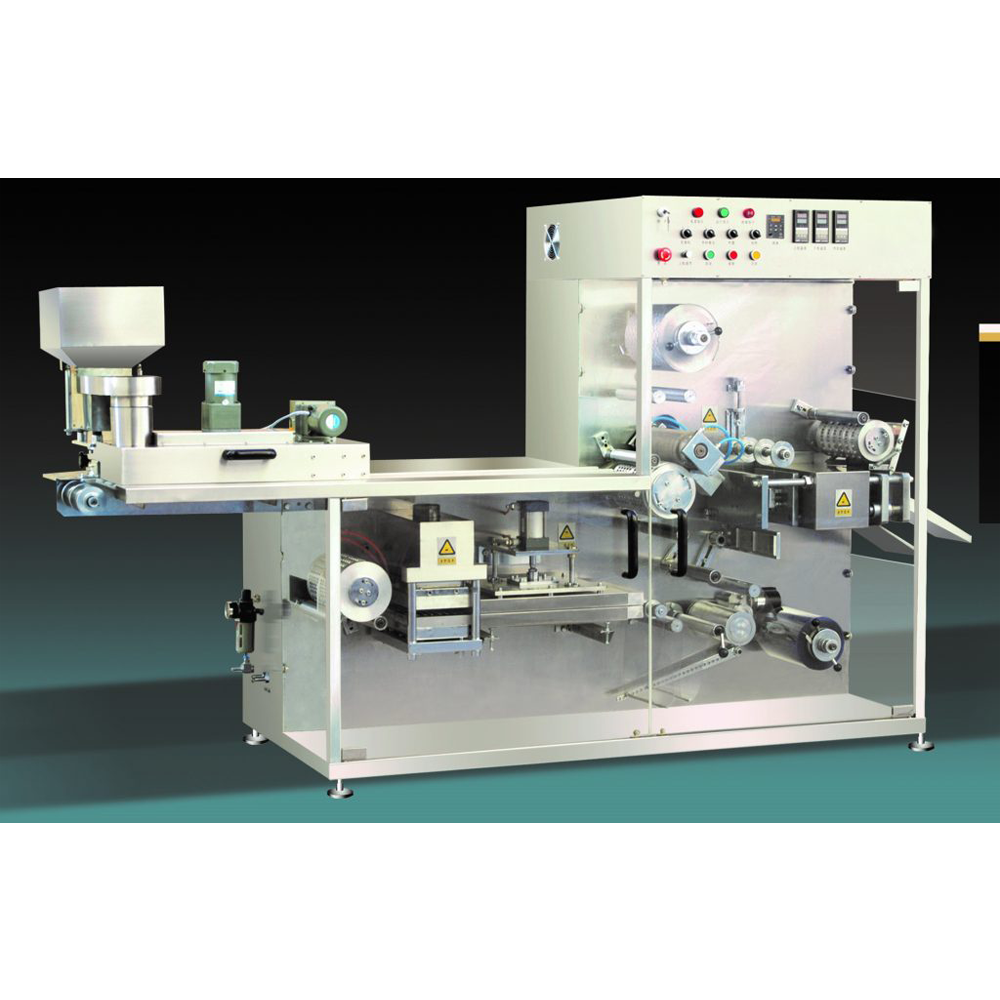

Description

This machine is suitable for pharmacy, medical machinery, foodstuff, electric, hardware industry’s capsule, tablet, syringe, ampoule, medical apparatus, food, electric appliance, hardware, blister package, etc.

Plate-model pressure blowing positively for the blister formation and hot sealing as well as high efficiency in packing. Mechanism hands for traction, stroke adjustable, easy operation, stable running. Can be matched to be in set of filling devices such as universal filer, converting head filer, disk vibrating filer. Can equip with PLC, human-machine interface, high atomization, photoelectron registration, localize heat seal, automatic error compensation. F-converting speed, high speed cutting ranged from 20 to 120times/pm. Note: Times in cutting depend on the plate’s length. Heating: inner heating. Automatic-control; Long length filling platform, highlight finishing rate, and also can be installed with conveying belt; Cooling: circulating water or otherwise using the tap water (outgoing connection); Cutting without waste left, saves the packing material up to 10%.

| MODEL | GBP-250A-I |

|

Punch frequency

|

capsule: ≤75times/min tablets:≤80times/min (frequency control) |

|

Max formation of sizes

|

200 x 240 x 12mm |

|

PVC sheet: thickness

|

(0.25-0.3) mm |

| Film W | 250mm |

|

Film diameter of PVC

|

Φ400mm |

|

Aluminum foil Thickness

|

0.02mm |

|

Film diameter of Aluminum foil

|

Φ280mm |

| Power |

380V, 50Hz, 9.2Kw

|

|

Air consumption

|

0.5-0.7 Mpa, 1.1m3/h

|

|

Water consumption

|

0.19 m3/h |

| Overall sizes |

2200 x 820 x 1700mm3

|

| Weight | 1,000kg |